|

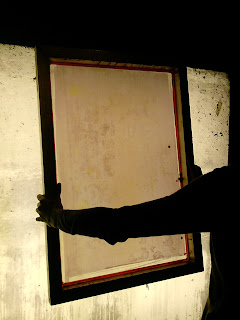

| My coated screen |

To produce a screen to print with, you need to prepare your screen. This process is called coating and exposing.This coating acts like a barrier to the parts of your design which is exposed.

Firstly I coated my screen. I done this by using light sensitive emulsion in a dark room. I poured the emulsion into a coating tray. I stood my silk screen against a wood board. I then held the tray against my screen until all of the emulsion had hit the screen. I pulled the tray up the screen ensuring that emulsion was hitting the screen constantly.I done this twice on both sides of my screen ensuring that I started to tip the tray back about 3 inches from the top of my screen.I then scraped any thick off using the tray holding it in a straight position. There should be an even coverage on both sides and no thick patches anywhere as this could result in poor exposure of the screen.

I left this to dry in a drying cabinet for 10-15 minutes ensuring nothing touched it and no wet screens were placed above or below it in the drying cabinet. Once this was fully dried, my screen was ready to have my designed applied to it. I cello taped my kodatrace (Drawing side down) onto to flat side of my screen. NOT the side which is shown in the picture above. I then placed it in the exposure unit with the kodatrace face down on the glass. My first attempt I put it into the exposure uni the wrong way up and it didn't expose at all. Be attentive to this because I have to strip and coat my whole screen again!! Typical. Design is a learning curve so always learn by your mistakes.

Once it has been exposed, the screen needs to be washed to remove the exposed emulsion which creates a stencil on your screen. If you have not done this before... the process will become clear as your doing it =)

I washed mine in a trough with a back light which makes it easier to see which parts hasn't been exposed. I washed it gently with a shower head using warm water... This softens the emulsion and the silk.

No comments:

Post a Comment